The G8D method provides a solution for analyzing issues primarily related to delivering defective products to the customer, described as NOK (Banica & Belu, 2019; Grecu at al., 2015). It allows for the analysis of whether the customer’s complaint is justified and, if so, what the root cause is. The root cause of the complaint must be determined at the supplier of the NOK product, which facilitates the application of the G8D method.

The G8D method helps protect the customer from receiving future defective products (Skotnicka-Zasadzień, 2018), enhancing the safety of the work and functioning of the final product being produced at the customer’s site, which, after the installation of a defective semi-finished product, could pose a threat to both the environment and the product itself. A similar approach is used in prefabricated construction, where defect analysis helps eliminate structural component flaws and improve the durability of prefabricates. Quality control and defect-cause analysis in construction are crucial for the longevity of structures and the safety of users.

The G8D method consists of eight steps, called disciplines, that enable both the identifying of the root cause of product defects occurring, as well as implementing actions to prevent their recurrence in the production process (Broday & Andrade, 2013; Cyganiuk et al., 2019a; Ramachandran et al., 2013). All steps of this method aim to protect the end customer from receiving future defective products. Unlike the 8D method (Dziuba et al., 2021; Kaplik et al., 2013), the G8D method includes an additional discipline, D0, which serves as preparation for the 8D method and aims to implement so-called Emergency Responsive Actions, designed to protect the customer from further delivery of defective products.

The G8D method requires the involvement of a team of specialists (Zhou et al., 2016), who not only understand the cause of the defect’s occurrence but can also identify where it occurs and how to correct the process. Their task is to implement the recommended changes in the production process to prevent the manufacturing of defective parts and to identify the point where the NOK part must be detected.

The G8D method requires the formation of a team, which must have a champion, who is responsible for making the final decision related to the solutions and recommendations developed by the team. The G8D team is a group with expertise in the problem being addressed in the G8D process and its scope. It may include designers, technologists, production or process leaders, quality department personnel, and others with useful knowledge for the G8D team.

The use of the G8D method yields the best results in companies that have implemented a quality management system according to ISO 9000 or 9001, where quality services are active and the production process is monitored at its various stages. This is related to access to the required documentation useful during the analysis of the problem being addressed, which the quality services have and use (e.g., SPC charts).

The G8D method is used in many production processes, regardless of the industry, to address customer complaints and fix defective products resulting from errors generated by the manufacturer. It is suitable for use when a quick response is required to a customer complaint, the generation of defective products has a complex nature, the root cause of the problem must be determined, the production process needs to be corrected, the recurrence of the issue prevented, and similar processes need to be updated.

Primarily, this method is used in the automotive industry (Borcz, 2003; Visser, 2017; Xu et al., 2018), from which it originates. However, it is also applied in the aerospace and metal industries, for issues such as: missing nuts, missing or incorrect hole dimensions, and incorrect bending radius. As can be seen, these are not complex defects; however, in the case of a higher number of errors on the part, additional G8D methods or, for example, the DOE method can be used.

Knowing the root cause of the product defect allows the identification of the point in the production process (the production equipment) where the defect is generated, serving as the root cause of its occurrence and the point in the process, called the escape point, where the defect should have been detected but was not, or where quality control was either not implemented or insufficient, resulting in the NOK component reaching the customer. The main document of the G8D method is the report (Zhou et al., 2016), which records all actions taken by the G8D team, including permanent corrective actions and recommendations for similar production processes with a probability of producing defective products. It also refers to the control points of the component in the production process.

The disciplines of the G8D method are supported by quality management tools (Hamrol & Mantura, 2002; Hamrol, 2012; Tangue, 2004) such as the Pareto diagram, Ishikawa diagram (Babica & Pająk, 2006; Celmerowski, 2007; Ramachandran et al., 2013), FMEA, and the 5 Why method (Celmerowski, 2007). A variety of quality management tools can be applied, and their selection for a specific problem depends on the G8D team. The D5 discipline of the G8D methodology allows for the selection and verification of permanent corrective actions for both the root cause and the escape point (Broday & Andrade, 2013; Lestyanszka Skurkova & Prajova, 2022). The G8D team, when selecting the best corrective method for a defective production process, must consider the benefits for both the process and the company, the risks (e.g., the potential failure of the chosen method), and the costs the company will incur in implementing the process changes. The task of the G8D team in this discipline is to select permanent corrective actions that are optimal for the company addressing a justified customer complaint. If the best corrective actions exceed the company’s financial and technological capabilities, they cannot be implemented. This means that the G8D team must propose the most optimal solutions, taking the established criteria into account. Properly selected optimal corrective actions in Discipline D5 enable the implementation of solutions that safeguard the process both from producing defective NOK parts and from failing to detect them during the process.

After identifying the root cause and the escape point using Discipline D4 of the G8D method (described in (Global 8D Solving Workbook, 2018; Cyganiuk et al., 2019b)), the next step in implementing corrective actions into the process is Discipline D5.

The objective of Discipline D5 is to select the best Permanent Corrective Actions (PCAs) to eliminate the root cause of the defect on the part and to choose the best permanent corrective actions addressing the escape point, as well as to verify the decisions made in relation to these selections (Zarghami & Benbow, 2017). In Discipline D5, it is crucial to make decisions about the best Permanent Corrective Actions (PCAs) for both the root cause and the escape point without being pressured by time constraints. Useful tools employed in Discipline D5 include brainstorming, the Poka Yoke method, risk analysis, pilot implementation of the solution, or other G8D methods. For PCAs, two criteria are essentially considered at the level of needs (Global 8D Solving Workbook, 2018):

- –

givens – this criterion must be met (it is obligatory), measurable, and achievable,

- –

wants – this criterion is worth considering, but it is not necessarily required to be fulfilled (critical).

Givens may include actions such as the required deadline for implementing corrective actions, the predetermined maximum cost of corrective actions, maintaining the delivery of defect-free products to the customer during PCAs implementation, or definitively resolving the problem of producing defective items in the analyzed process and similar processes (Global 8D Solving Workbook, 2018).

Wants may include factors such as the swift implementation of PCAs, no impact of PCAs implementation on cost increases, or a short timeline for implementing corrective actions (Global 8D Solving Workbook, 2018). The steps which should be taken during the implementation of Discipline D5, enabling the introduction of PCAs for the root cause and the escape point, are presented in Figure 1.

Procedure algorithm for Discipline D5 of the G8D method (elaboration based on Global 8D Solving Workbook, 2018)

The procedure algorithm shown in Figure 1 indicates a parallel analysis for selecting PCAs for both the escape point and the root cause. In the case of the root cause, the algorithm indicates that the procedure in Discipline D5 should begin with the availability of a verified list of root causes. For the escape point, we must have proof that the control system for the produced part needs improvement or modernization. The next step is to establish the criteria for selecting the best PCAs for the root cause and the escape point, with the criteria being set by the members of the G8D team, who first and foremost consider the “givens” criteria. After the criteria have been established, the possible PCAs for both the root cause and the escape point should be selected, considering all proposals that will resolve the problem of producing defective products. In the case of the escape point, the previously applied Interim Containment Actions (ICA) must also be taken into account.

The next step is to select the optimal PCAs for both the escape point and the root cause. Among the proposals recommended by the G8D team, the solution is selected that allows for the use of technologies available within the company and does not require significant financial investment. Changes introduced, even at a low cost, can prove to be groundbreaking for the production process.

After selecting the appropriate PCA, the choice is verified. If the selection proves to be correct, does not involve significant costs, and according to the team members, will enable the process to be free from the production of defective products, it is presented to the group leader, known as the Champion, who has the final decision regarding the selection of PCAs for the escape point and the root cause. Completing the procedure according to the algorithm shown in Figure 1, verified permanent corrective actions for the root cause and the escape point are obtained.

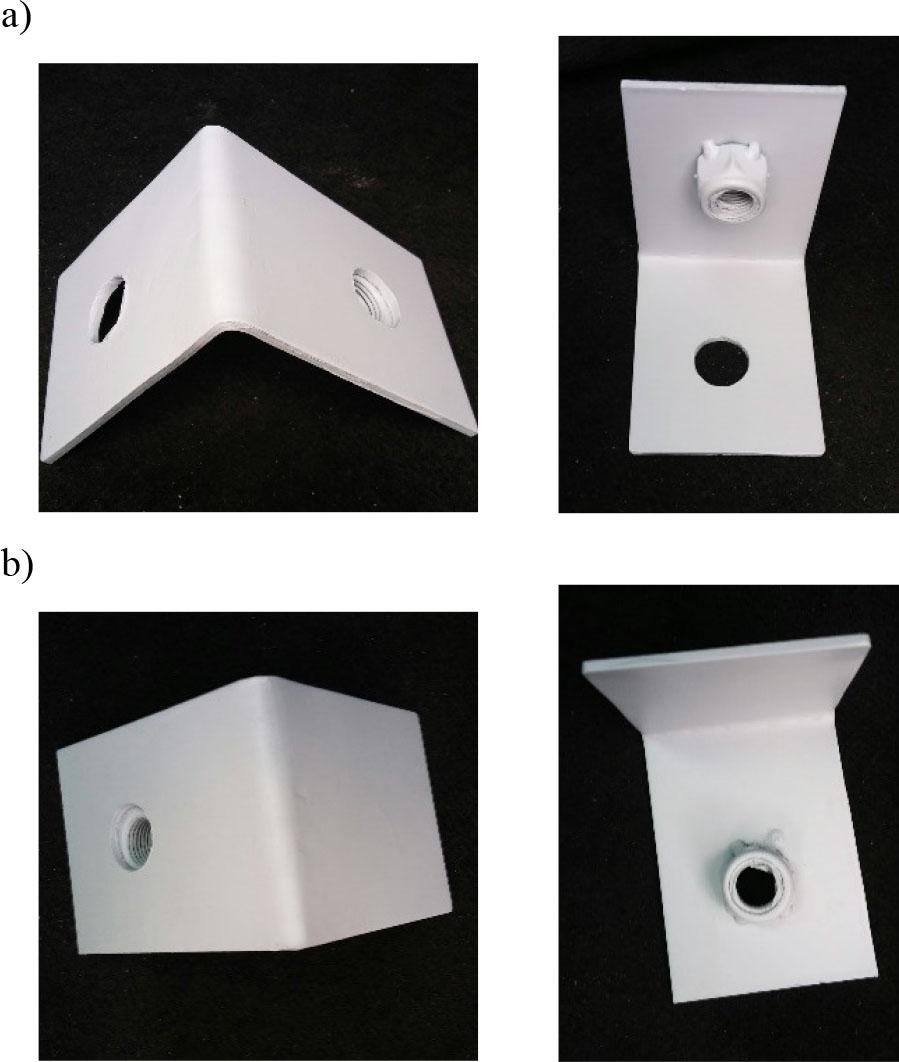

The inspection at the client who reported the defective product revealed that parts were delivered in the form of V-bent metal plates without one of the two drilled holes, which are necessary to fasten the plates to the finished product. The complaint was accepted, and during the problem analysis process using the G8D method, Discipline D2 indicated a problem: the omission of the drilling process before performing the bending, nut welding, and painting processes for the part. The correctly manufactured part and the defective part are shown in Figure 2. In Figure 2a, a correctly made part can be seen, with two through holes. Figure 2b illustrates the defective part, in which the absence of the second hole was detected, which was the reason for the customer’s complaint. This defect was discovered by the customer during the assembly process.

Part that is the basis for the customer’s justified complaint: a) correctly manufactured, b) defective NOK (own research)

As the inspection at the production workstation for the part where the holes were made (Cyganiuk et al., 2022) showed, the worker occasionally skipped the drilling process and only performed the control measurement on one hole due to the same hole dimensions in the metal plate. The analysis of the production workstation in Discipline D4 showed that the production process is vulnerable to such actions of the worker and requires the implementation of technical solutions to the root cause, which is the lack of equipment supervision over the drilling process and the lack of verification of both holes by the worker. Due to the worker’s omission of hole measurements, a decision was made to also modernize the escape point by using a solution that minimally engages the worker and does not require them to carry out the hole diameter measurement.

The G8D team used two quality management tools in the D5 discipline, which were brainstorming and the Poka Yoke method, applied to the design of the fixture stands. Brainstorming allowed the generation of three viable ideas to secure the production process against omitting the drilling process. One of these was the use of the Poka Yoke method, which mainly resulted from the analysis of the drill operator’s work and was adopted as the final solution. According to the G8D team, this was the only effective method at the drilling station, allowing the process to be safeguarded against errors. Brainstorming, on the other hand, additionally generated a solution involving the division of the drilling process into phases.

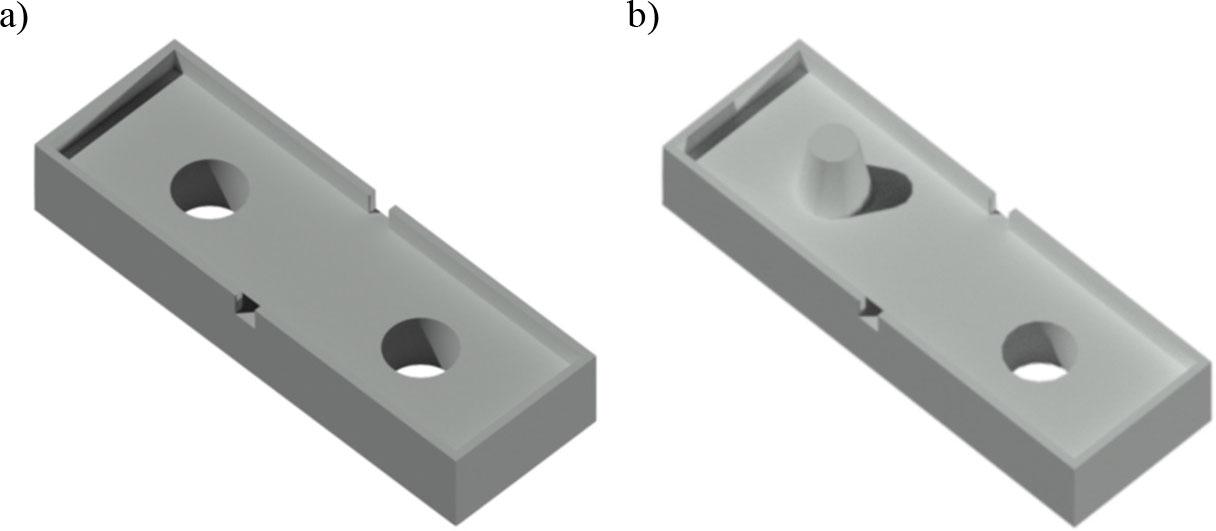

The G8D team, after analyzing the drill operator’s work, selected the simplest form of process safeguard to prevent the omission of drilling a hole. It was decided to divide the drilling process into two phases and prepare appropriate fixture stands to position the metal plate during the drilling process, as shown in Figure 3. In this figure, two fixture stands are shown, one for the first phase of drilling (Fig. 3a) and the other for the second phase of drilling (Fig. 3b). The fixture stand for the first drilling phase is equipped with symmetrically distributed holes (Fig. 3a), allowing the first hole to be drilled regardless of the direction in which the plate is mounted on the drill press (right/left). This safeguards the process from damaging the fixture stand with the drill. The designed fixture stand for the first drilling phase is shown in Figure 3a. The fixture stand, before the modification, was equipped with only one hole. The second phase of drilling the hole in the metal plate required a clear positioning safeguard in the fixture stand (in Figure 3b, the fixture stand for the second drilling phase can be seen), ensuring that the second hole would be drilled and preventing both the omission of drilling and the duplication of drilling on the same hole made during the first phase. The stabilization of the metal plate is achieved by a pin mounted on the fixture stand (the design of the fixture stand is shown in Figure 3b).

Design of fixture stands for securing the metal plate during the drilling process: a) fixture stand for the first drilling phase, b) fixture stand for the second drilling phase (own development)

The method using the fixture stand required minimal financial investment compared to other proposals considered by the G8D team. All the fixture stands could be produced using materials (S235JR) and manufacturing technologies (milling, drilling, turning) available within the company. The second conception was to modernize the drill control system by adding sensors (inductive) and a PLC controller, which would allow the counting of the movements of the drill head within the required operational time. Another solution that was considered involved a system for counting the number of metal plate fixings on the non-modified fixture stand, where an inductive sensor and a counter, among other components, would also need to be used. The fixture stand had to be rotated at the workstation each time.

The fixture stands for securing the metal plate and the division of the drilling process into two phases were used as a solution to the root cause of the problem, mainly due to the low financial costs and the ability to manufacture the stands using the company’s own materials.

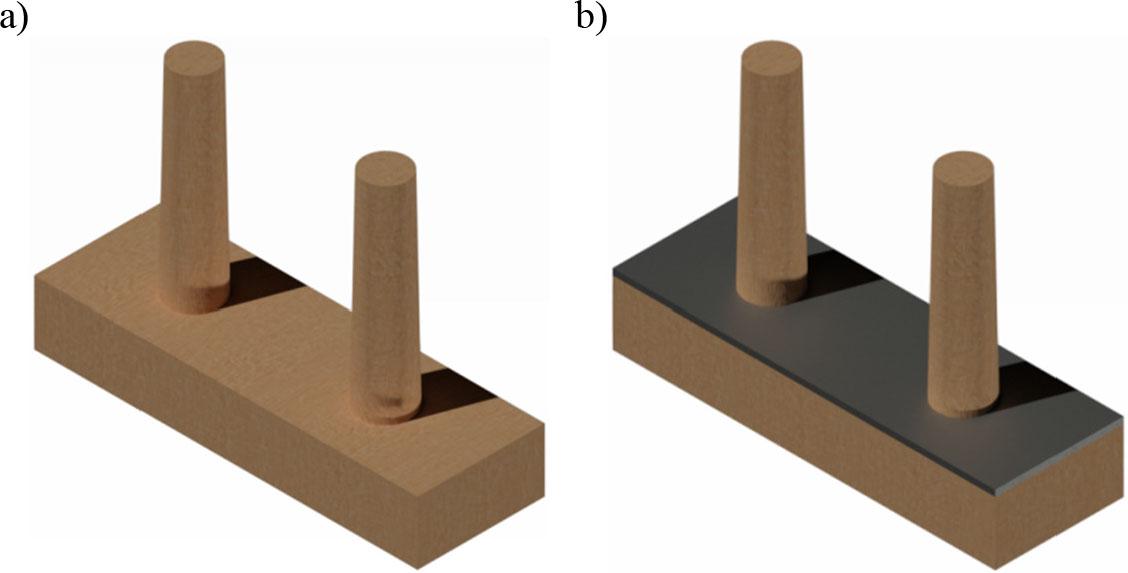

In the case of the escape point, it was necessary to implement a new first step in the product inspection process at the workstation, different from the previously used method (diameter measurement), because the inspection was not being performed correctly due to measuring on a single hole. A simple method of control for both holes was applied for the escape point. In this case, the G8D team decided to use a fixture stand with two pins functioning as a gauge for hole control, as shown in Figure 4. Figure 4a illustrates the fixture stand, while Figure 4b shows the fixture stand with a correctly drilled plate placed on it. The two pins used in the fixture stand shown in Figure 4 ensure that if the drilling operation is omitted and the hole is missing in the plate, the plate cannot be placed on the fixture stand due to the pins, which are designed to fit into the hole of the plate. The gauge was made from oak wood.

Design of the fixture stand for controlling both holes at the drilling workstation: a) empty fixture stand, b) fixture stand with the metal plate placed on the stand after the drilling process (own research)

The diameter measurement of the holes was transferred to the responsibility of the quality team. It includes the required measurement of both holes on a randomly selected sample of the produced parts.

As can be seen, discipline D5 enabled the development of solutions that secure the production process against omitting the drilling operation. D5 allows for the move to the next discipline, D6, where the solutions proposed in D5 will be implemented in the production process.

The G8D method helps protect not only the customer from losses but also the manufacturer from accumulating time and financial losses. In the case of the analyzed problem, the costs incurred by the manufacturer of the defective part included the costs of the customer’s complaints and the costs of defective products in the warehouse ready for shipment, i.e., the costs for the total number of defective products produced (4450 in total – 3200 units with the customer and 1250 in the manufacturer’s warehouse), the costs of workstation modernization, including the production of fixtures for the drilling process and special clamping jigs to secure the fixtures to the drill press table (cost of implementing corrective actions), as well as the costs of conducting the initial trials. In the case of applying Discipline D0, additional costs included: inspecting the part on-site at the customer’s location, as well as implementing actions from Discipline D3 to perform a 100 % inspection of the parts being sent to the customer.

It can therefore be observed that the G8D method not only allows for verifying the problem and implementing corrective actions (Discipline D6) but also for analyzing costs, which include several factors. In the analyzed example, these are five factors that have a significant impact on the final cost of defect-free production.

Analyzing time efficiency, the use of the G8D method allows for a significant reduction in the time spent analyzing the root cause of the error, primarily due to the knowledge of the G8D team members, who, based on the symptoms, are able to quickly identify the actual or likely causes of the defective product, which are then verified. The remaining time consumption pertains to the same aspects as in the case of costliness.

Each of the mentioned disciplines of the G8D method requires both time and financial investment, and this investment varies depending on the complexity of the problem being solved or its level of difficulty.

The G8D method helps protect the customer from receiving defective products or semi-finished goods, increasing the safety of manufacturing non-defective products. It is a comprehensive method that allows for a step-by-step analysis to identify and resolve the root cause of errors in the production process that lead to the production of defective products.

The G8D method, particularly its fifth discipline, effectively reduces the number of defective products. In industrial construction, the application of defect analysis methods enables the optimization of production processes, contributing to improved quality and durability of prefabricated building elements. The implementation of permanent corrective actions enhances process quality and reduces costs associated with complaints. Similar techniques can be applied in prefabrication, where analyzing each defect can help eliminate errors and improve the production process of industrial prefabricates.

Discipline D5 allows the G8D team to analyze possible solutions for the problems that have occurred, and the procedure algorithm facilitates the step-by-step proposal and selection of a fixing process. The customer is always the most important, but the company must also consider its own financial interests. Therefore, the proper use of discipline D5 is crucial, as through detailed analysis, the team can select the method from among many production process modernization ideas that not only secure the process against the production of defective products but also allow the company to utilize its own technologies and materials, minimizing human, infrastructure, and financial resources. This applies to both the root cause and the escape point. Both modernization solutions (root cause and escape point) can be worked on simultaneously, and the final choice of the solution to be implemented, from the many proposals presented by the G8D team, always rests with the group Champion.

In the presented example of applying the D5 discipline algorithm, it can be seen that the proposed solution for the root cause, after a slight modification, could also be applied to the escape point. However, the dimension control of the holes in the metal plate had to be transferred to the quality team’s responsibilities, relieving the drill operator from additional tasks and allowing him to focus on the drilling process. With this approach, the probability of producing defects was eliminated, which is the purpose of the implemented corrective solutions.

Based on the conducted analysis, it was found that in the case of the drill press operator, the simplest solution to the problem was also the most effective, and an effective method of preventing mistakes is a check that simultaneously allows for the proper placement of completed parts. An additional advantage of this solution is that the gauge can also serve as storage for finished products, which would require its modernization in terms of the pin height or an increase in the number of these gauges. The plate working as a gauge could also be used not only as a convenient storage but, after modernization, also as a pallet for transporting finished parts.

The next stage of the process carried out using the G8D method is to permanently implement the proposed solutions in the production process and analyze similar processes where the proposed method will bring benefits and secure the defect-free production process.

As can be seen from the presented example, the G8D method is suitable for use wherever there is a justified customer complaint, and it is also effective in all manufacturing industries, especially when supported by additional tools used in quality management.