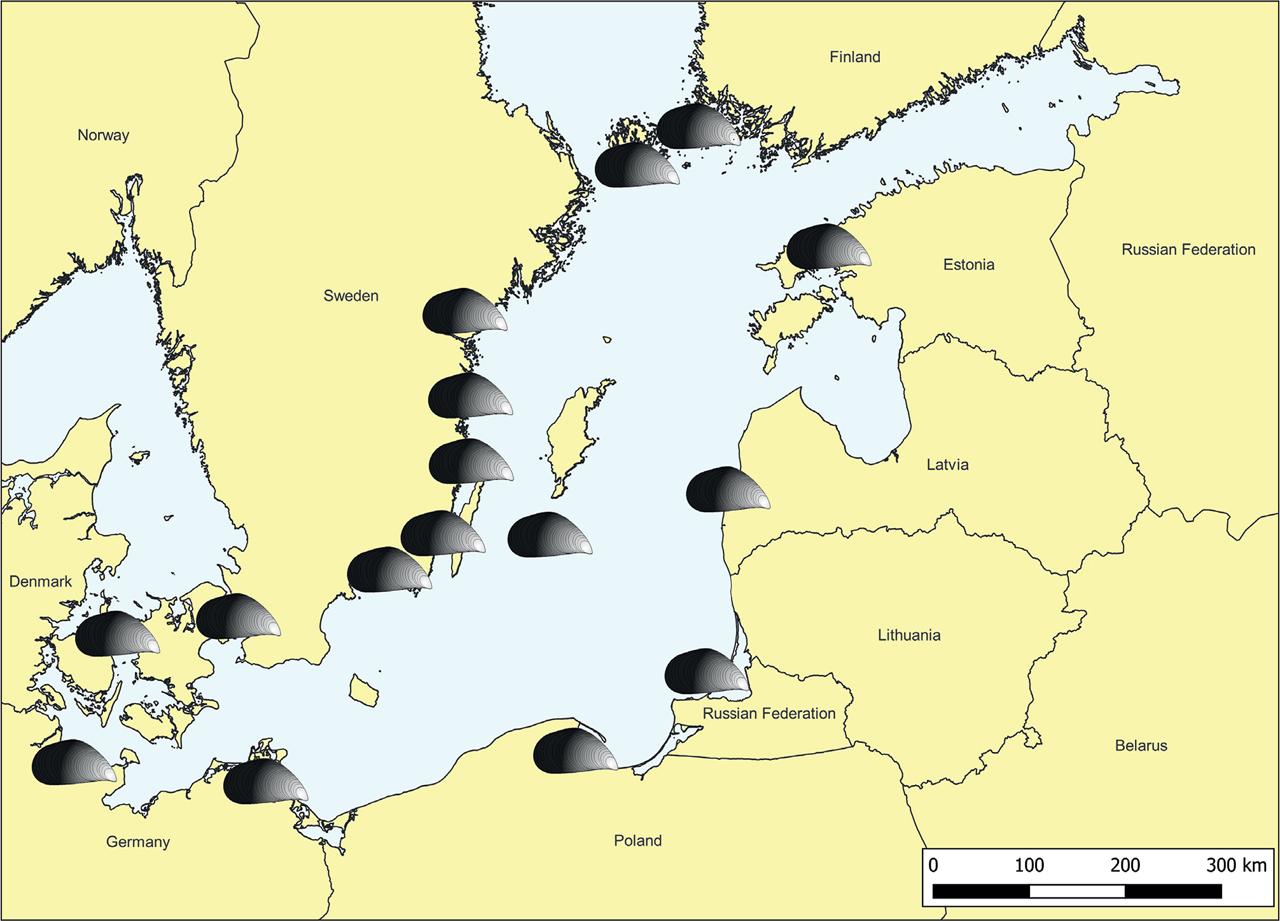

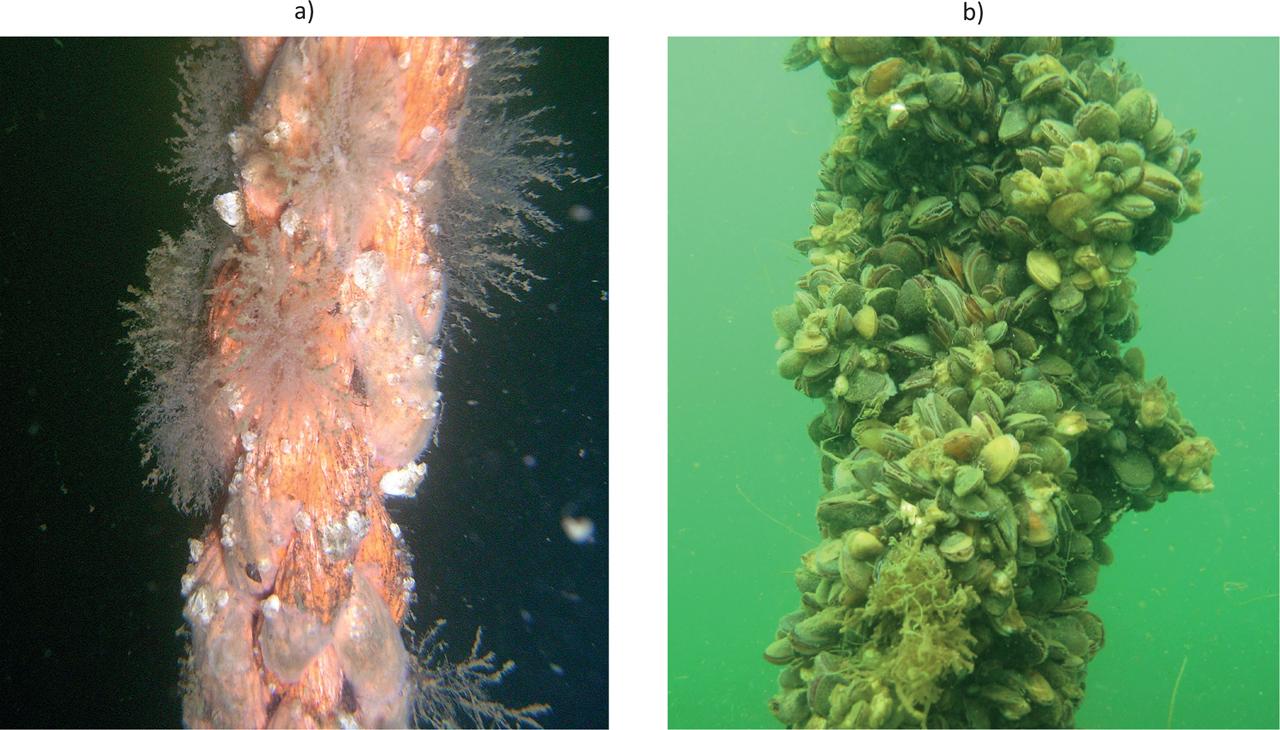

Figure 1

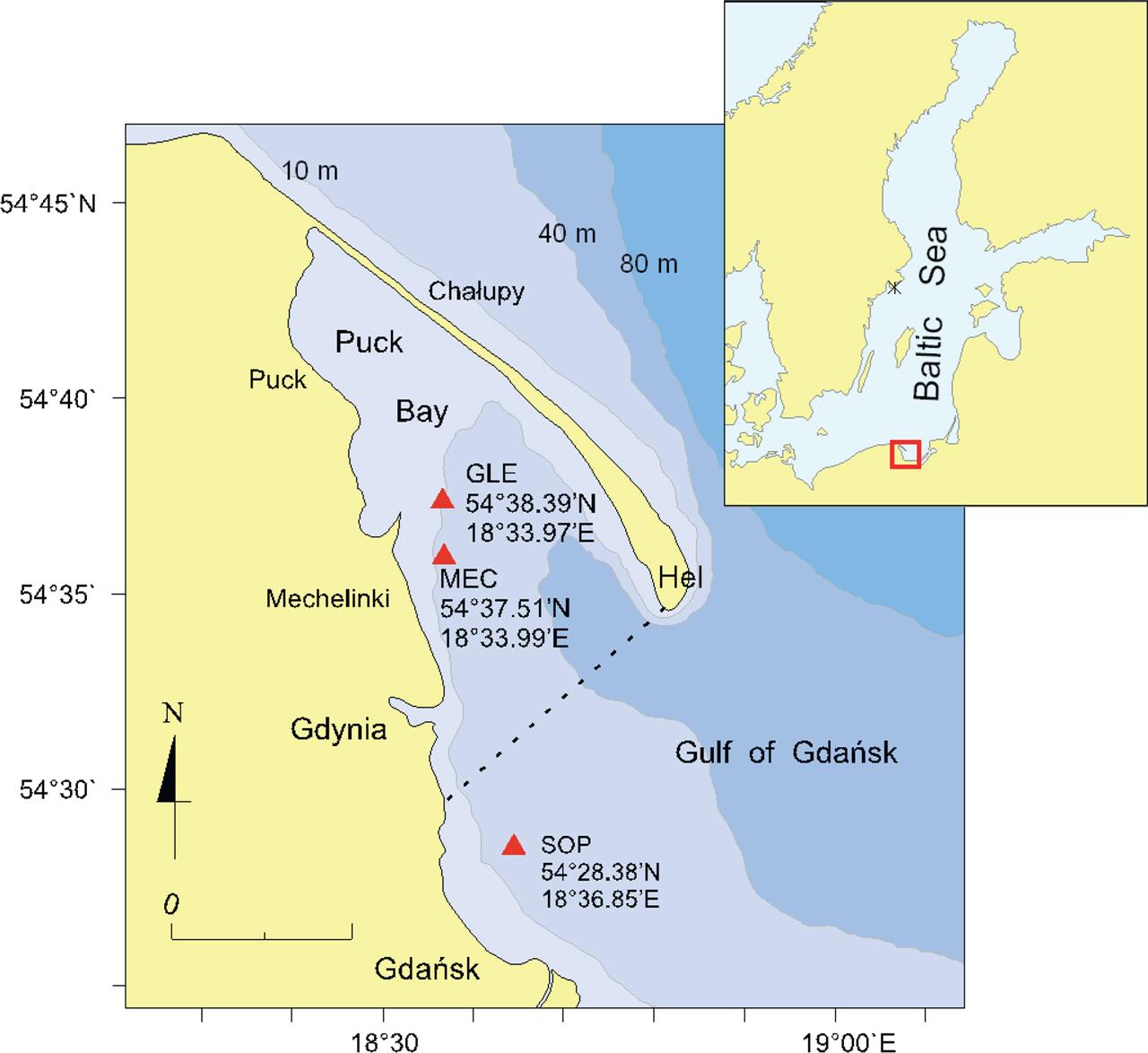

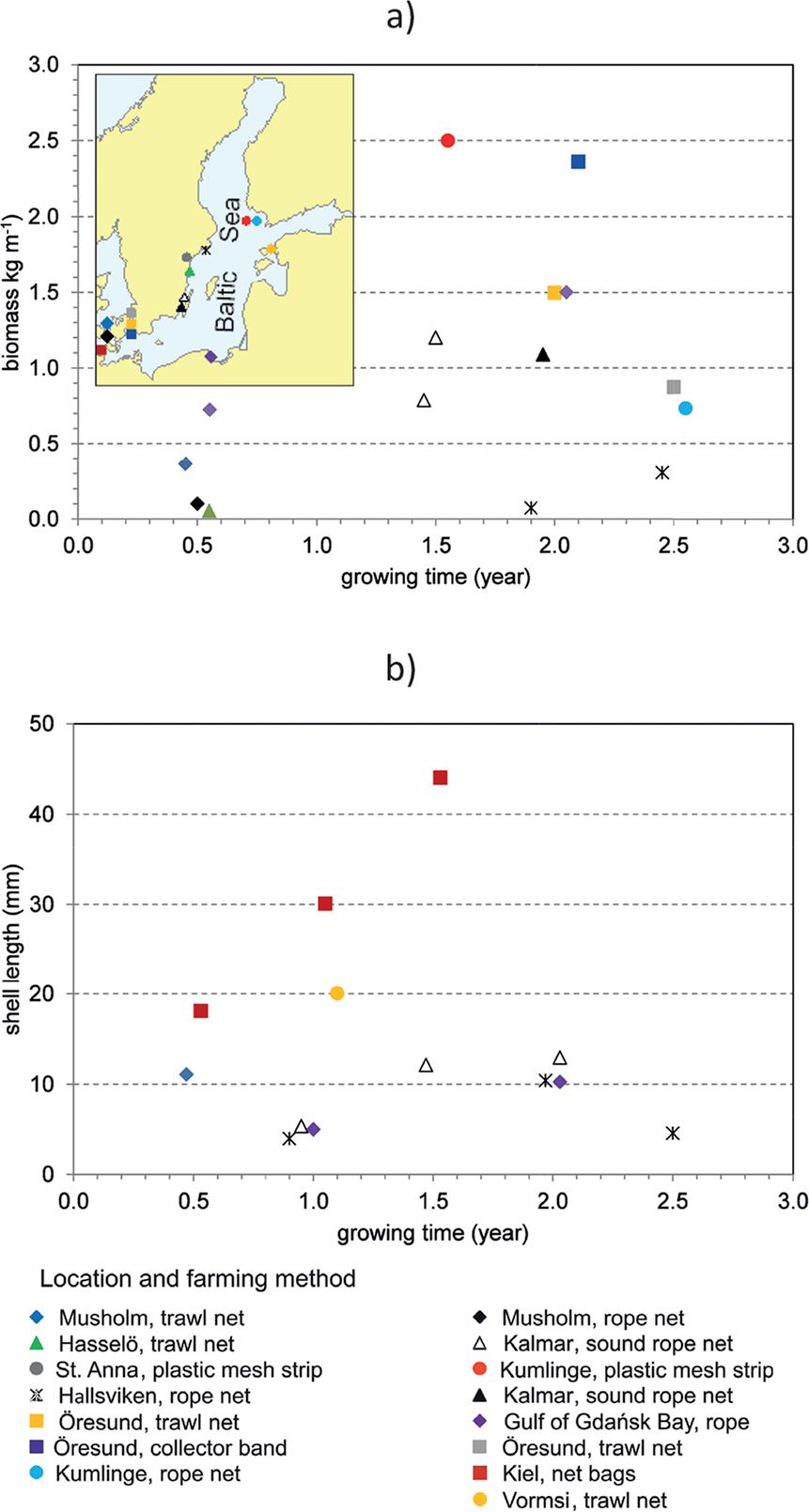

Figure 2

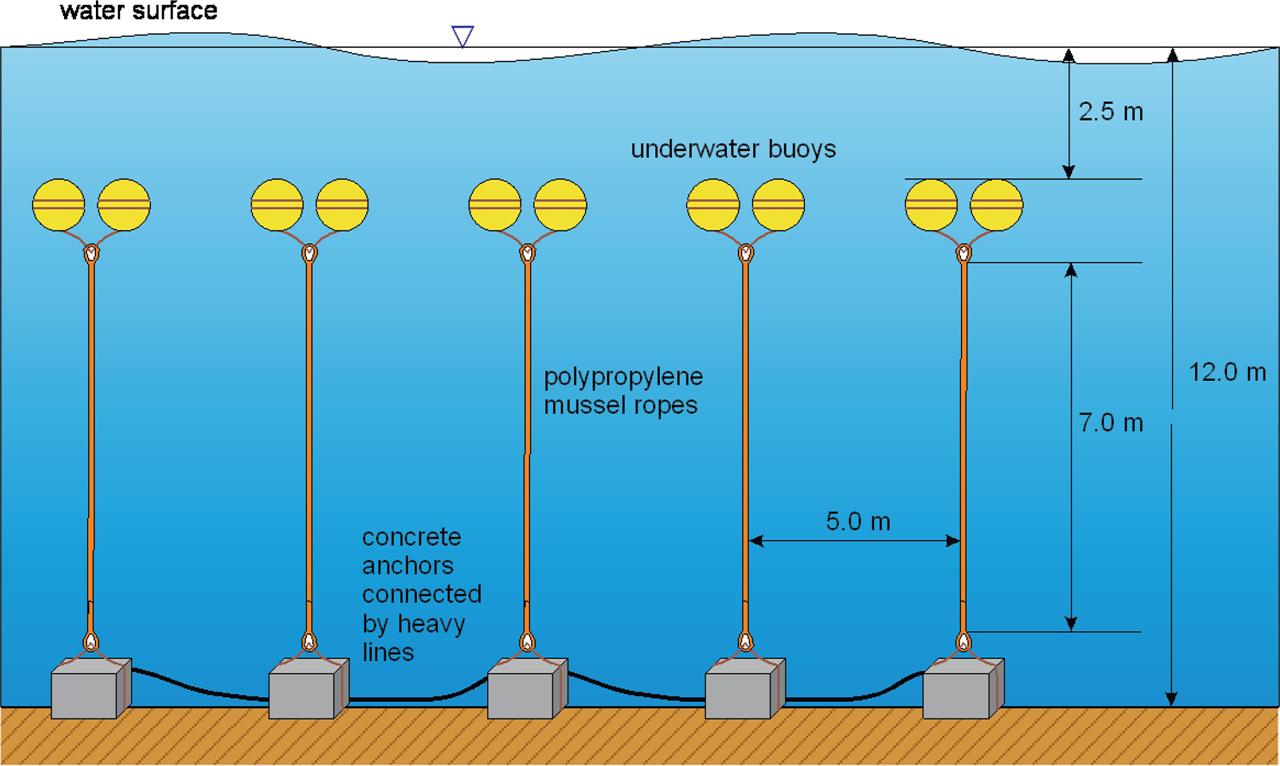

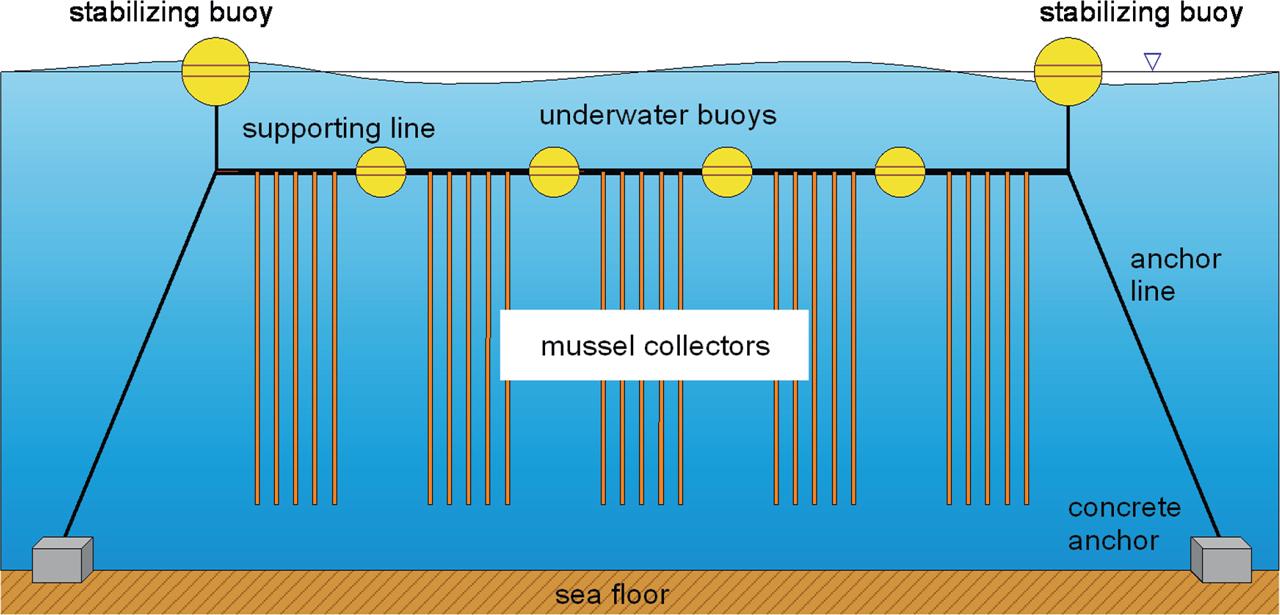

Figure 3

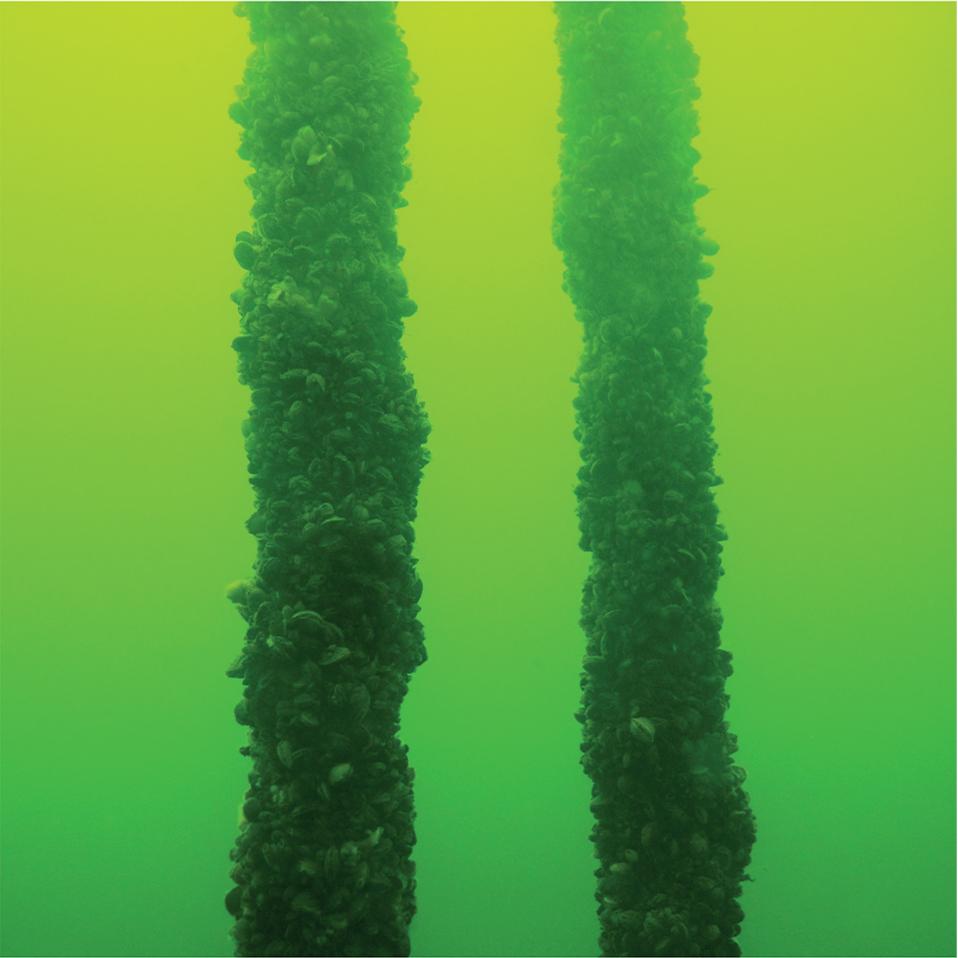

Figure 4

Figure 5

Figure 6

Figure 7

Estimated costs (EUR) of materials (including shipping) required for one 200 m long long-line module and equipment used for mussel harvesting in the long-line system

| Component | quantity | price |

|---|---|---|

| Polypropylene twisted rope (32 mm diameter) used as the main and anchoring lines (including provision for ties and loops) | 260 m | 491 |

| Polypropylene braided hawser rope (32 mm diameter) used as a growing line (including provision for securing ends) | 2860 m | 6111 |

| Polypropylene twisted rope (18 mm diameter) for tying up growing lines and buoys | 440 m | 265 |

| Polypropylene twisted rope (6 mm diameter) to prepare loop cords for setting attachment points on the mainline | 220 m | 15 |

| Submersible buoys with a buoyancy of 35 dm3 | 38 items | 970 |

| Self-made concrete blocks (anchors) of 1.5 t (including the cost of purchasing concrete, materials to build wooden molds, reinforcing bars, stainless steel rods for line attachment loops) | 4 items | 703 |

| TOTAL | 8555 | |

| Basic harvesting equipment (stripping and declumping/sorting machines) | 22374 |

Selected technical parameters of the culture module in the long-line system

| Parameter | ||

|---|---|---|

| Length of supporting line/head rope | 200 | m |

| Length of growing rope (collector) | 7 | m |

| Diameter of head rope | 32 | mm |

| Diameter of growing rope | 32 | mm |

| Buoys buoyancy | 35 | dm3 |

| Number of buoys | 30 | |

| Total length of growing ropes | 2800 | m |

Average length (mm) and growth rate (mm year−1) of mussels on ropes as a function of exposure time, depth zone and location of mussel farming site in the Gulf of Gdańsk in 2009–2012 (Sami Alias 2014, modified)

| Exposure time (year) | Depth zone (m) | MEC | GLE | SOP | |||

|---|---|---|---|---|---|---|---|

| Mean shell length | Shell growth rate* | Mean shell length | Shell growth rate | Mean shell length | Shell growth rate | ||

| 1 | 3–4 | 6.7 | 6.7 | 5.8 | 5.8 | 4.2 | 4.2 |

| 5–6 | 6.2 | 6.2 | 5.4 | 5.4 | 3.7 | 3.7 | |

| 7–8 | 7.0 | 7.0 | 5.4 | 5.4 | 3.0 | 3.0 | |

| 9–10 | 4.7 | 4.7 | 4.4 | 4.4 | 3.2 | 3.2 | |

| 2 | 3–4 | 9.0 | 4.4 | 11.3 | 5.5 | 10.0 | 4.9 |

| 5–6 | 9.6 | 4.7 | 14.2 | 6.9 | 9.0 | 4.4 | |

| 7–8 | 9.2 | 4.5 | 11.1 | 5.4 | 7.2 | 3.5 | |

| 9–10 | 12.4 | 6.0 | 10.6 | 5.1 | 9.7 | 4.7 | |

| 3 | 3–4 | 7.8 | 2.6 | 13.1 | 4.3 | ||

| 5–6 | 11.8 | 3.9 | 8.5 | 2.8 | |||

| 7–8 | 7.2 | 2.4 | 13.1 | 4.3 | |||

| 9–10 | 9.8 | 3.2 | 7.3 | 2.4 | |||

Summary of biological parameters of mussels Mytilus trossulus harvested in the Gulf of Gdańsk and other selected Baltic areas_ Technical details of the experimental set-up in the Gulf of Gdańsk are given in the text_

| Parameter | (this study) | (Taylor et al. 2019) | (Kotta et al. 2020) | |||

|---|---|---|---|---|---|---|

| Puck Bay (Gulf of Gdańsk) | Limfjorden | Kumlinge (Åland archipelago) | Sankt Anna (Östergötland archipelago) | Kiel (Bay of Kiel) | ||

| farming period | 2009–2011 | 2017–2018 | 2010–2012 | 2016–2018 | 2011–2012 | |

| farming technology | long-line | long-line | nets | spat catching ropes | ropes with collector bands | |

| total wet biomass (soft tissue and shell) and SFDW (kg m−1) | 1.60/0.142 | 0.72/– | 3.40/– | 2.5/– | ||

| total biomass production (wet soft tissue and shell; t ha−1) | 22.4 | 41.0–90.4 | 16.0* | 20.4* | 16.7* | |

| mean content of C/N/P in SFDW** (%) | 48.6/9.8/1.1 | –/3.2–3.8*** /0.6*** | –/4.4*** /0.6*** | –/5.6–7.5*** /0.6*** | ||

| content of elements in SFDW per 1 m rope (g m−1): | C | 80.5 | ||||

| N | 16.2 | 3.7 | 23.3 | 22.3 | ||

| P | 1.8 | 0.3 | 1.8 | 1.6 | ||

| yield of elements in one t of harvested mussels (kg): | C | 43.1–43.7 | ||||

| N | 8.3–8.7 | 13.7 | ||||

| P | 1.0 | 0.9 | ||||

| maximum total removal of elements (kg ha−1): | C | 1159 | ||||

| N | 234 | 600–1270 | 83 | 140 | 148 | |

| P | 26 | 40–100 | 6.4 | 10.8 | 10.8 | |